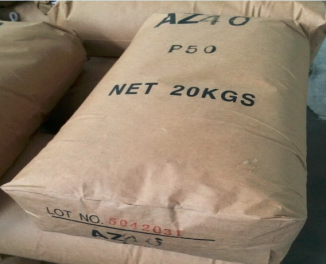

Alumina Zirconia Abrasive Grains

【Introduction】: Alumina Zirconia Abrasive Grains (AZ) represents a fused Alumina-Zirconia type of

eutectic composition produced by melting alumina and Zirconia at about 2000℃ temperature

in an electric arc furnace followed by cooling of the motion product.

【Grade】:

AZ40 : Al2O3:58~60%; ZrO2:38~40%

It promises lasting durability for coated and bonded abrasives. The very fine and homogenous microstructure of

this material provides high toughness but also excellent self-sharpening properties.

AZ25 : Al2O3:74~76%; ZrO2:23~25%

It is extremely wear resistant and anti-friable grain that is widely for bonded abrasives.

AZF25 : Al2O3:74~76%; ZrO2:23~25%

It is a dense, durable material frequently used to produce heavy-duty bonded abrasives.

AZS25 : Al2O3:74~76%; ZrO2:23~25%

It is extremely tough and hard with blocky shape and is re-shaped based on the original AZF25 material.

It is frequently used for producing extra-duty bonded abrasives for steel conditioning industry.